ELBOW & IN-LINE BALL CHECK VALVES

Designed to resist clogging, effectively prevent reverse sewage flow, and provide easy service access in pumping stations, which greatly simplifies daily operation.

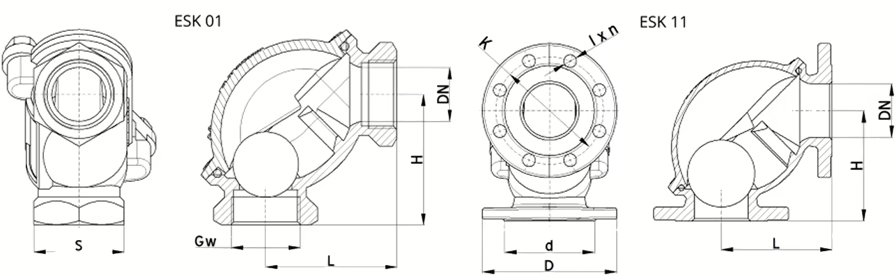

ESK 2-in-1

Elbow + Check Valve

Designed to replace a standard pipeline elbow, the ESK valve reduces installation complexity by eliminating one flange connection. Available in two configurations—ESK 01 with threaded connections and ESK 11 with flanged connections. Suitable for both horizontal and vertical sewage pipeline installations.

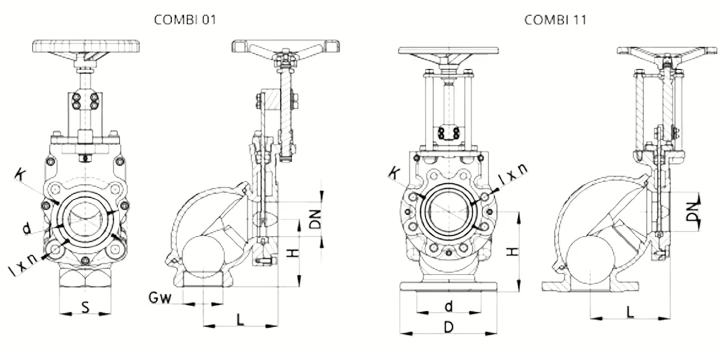

COMBI 3-in-1

Elbow + Check Valve + Knife Gate

Combines the functions of an elbow, check valve, and integrated knife gate into a single, space-saving solution. Available in two configurations: COMBI 01 with a threaded inlet and flanged outlet, and COMBI 11 with flanged connections on both ends. The built-in knife gate allows instant manual shutoff, ensuring dependable isolation in waste lines—even in demanding, solids-laden applications.

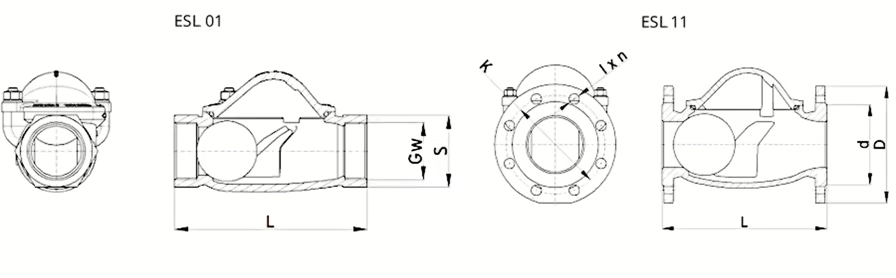

ESL In-Line Ball Check Vavle

Linear Check Valve

A straight, in-line ball check valve designed for efficient flow and reliable backflow protection. The ESL valve automatically closes when the pump stops, helping safeguard waste line systems without manual intervention. Available in two configurations: ESL 01 with threaded connections and ESL 11 with flanged connections.

Why Choose ekoWODROL Ball Check Valves for Pumping Stations?

Minimize Service Time

Service a DN80 (3 in) valve in just 5 minutes—compared to up to 20 minutes with traditional solutions—saving time and reducing downtime.Maximum System Access

Full access to the interior, including the ball, allows many maintenance tasks without full disassembly. The cover can even be placed in a convenient service position for easier work.Simplify System Design

Compact 2-in-1 (elbow + check valve) and 3-in-1 (elbow + check valve + knife gate) solutions reduce the number of flange connections, streamlining installation.Professional Technical Support

From valve selection to ongoing assistance, we provide expert guidance and support throughout the valve’s service life.Fully Customizable

Szuster valves are like building blocks for engineers. With three main types—ESK (Check Valve + Elbow), COMBI (Check Valve + Elbow + Knife Gate), and ESL (Linear Check Valve)—plus a wide range of versions and options, they can be tailored to fit the specific needs of any installation.

Ball Check Valve Diagrams:

Additional Check Valve Versions:

Additional Check Valve Versions:

| Valve Type | Key Benefits | Typical Applications |

|---|---|---|

| Long Version (L) | Full free passage for the nominal-diameter ball, minimizing clogging and ensuring smooth flow. | Pumping stations with solid matter separation, pneumatic pumping stations |

| Floating Ball (F) | Automatically prevents backflow with a lightweight floating ball (~0.8 g/cm³). | Backflow prevention systems |

| Quasi-Floating Ball (Q) | Provides controlled flow with a quasi-floating ball (~1.02 g/cm³) for reliable operation under variable conditions. | Pneumatic pumping stations, sewage pumping stations, pumps with frequency converters |

| With Drainage (D) | Includes a convenient drain plug for quick maintenance and system draining. | Pump units, dry pumping stations, gravity systems with backflow valves |